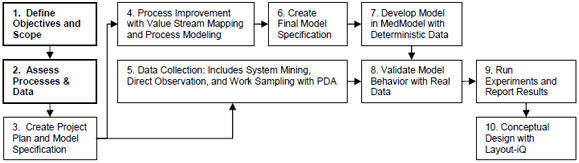

Simulation Modeling - How It Works!

1. Define Objectives and Scope

a. List the Specific Issues to be Addressed – Questions that need to be Answered.

b. For each Issue/Question identify specific goals, targets, or objectives.

c. Create a Mission Statement for the project that includes Objectives and Scope.

2. Assess Processes and Data

a. Evaluate key measures of system performance (e.g. - average length of stay,

resource utilization, throughput, etc.). If key metrics do not exist, then perform

utilization studies to measure the key performance metrics. Use “Work

Sampling” or “Direct Observation” with the PDA’s for data collection. Look for

hidden opportunities in processes, resources, and design performance. Add

relevant issues/questions that are discovered.

(PDA Demonstration)

b. For each Question/Issue listed above, identify all Processes and Dependent and

Interdependent Resources that need to be included in the analysis.

c. Determine if you can solve questions/issues with the same model, or does it

make sense to build multiple models to solve for specific questions/issues.

d. Identify the Appropriate Methods to Solve for each question/issue.

i. Spreadsheet Analysis

ii. Linear Programming

iii. Value Stream Mapping

iv. Deterministic Modeling

v. Queuing Theory

vi. Discrete Event Simulation

e. Given the Modeling Methods selected, make a list of process and data

requirements for each model.

f. Determine the desired outputs and inputs of each model.

g. For each process… determine whether the process has been documented. If the

process is not currently documented, then allocate time in the plan to document.

h. For data… determine whether the data exists in the organization. If the data

does not exist, then allocate time in the plan to collect the data.

3. Create a Project Plan and Model Specification

a. Create an MS Project Plan with tasks and timelines and an estimate of the

required Resources needed to do the Study.

b. Summarize each Model to include the issues and questions it will solve for, the

expected outputs and inputs, and a description of how the model will solve the

problem.

c. Present the Project Plan and cost estimate to the client.

4. Process Improvement with Value Stream Mapping and Process Modeling.

a. Document Processes using Value Stream Mapping/LEAN

b. Assign each Process step to value-added/non-value-added.

c. Identify waste in the process and re-create the process without the waste.

d. Use ProcessModel on cases where significant variation and interdependency exist.

5. Data Collection

a. Data Mining – Extract relevant data from hospital computer systems and existing

databases.

b. Data Collection – Establish a data collection methodology for all data needed that

cannot be collected through data mining using the PDA’s and other methods.

c. Data Modeling – Model patient arrival patterns, cycle times, etc.

6. Create Final MedModel Model Description and Specification

a. Include all updated processes and lessons learned from steps 4 and 5 into the simulation model description and specifications.

7. Develop MedModel Model (See Attachment for Detailed Process)

a. Build with Theoretical data first to verify the Logic.

b. Add real data to the model and validate model outputs.

8. Validate the Model with Real Data

9. Run Experiments and Report Results

10. Test Design Concepts with Layout-iQ.

a. Test Design concepts with Layout-iQ

b. Choose the Modeling Method (e.g. – Process/Routing, From/To, Subjective).

c. Collect the Data.

d. Standardize/Normalize the Dataset (Flow per Patient Bed per Hour).

e. Develop a conceptual layout in AutoCAD

f. Export the AutoCAD drawing in .wmf file format.

g. Build Layout-iQ model using the wizard.

h. Develop baseline model; usually a model of the “As Is” condition.

i. Model flows in Baseline model.

j. Use diagram to guide change process.

k. Create alternative layouts.

l. Compare “Total Travel Distance” and “Aisle Effectiveness”.

(Layout-iQ Demonstration)

(ProcessModel Demonstration)